How to build a ukulele from scratch

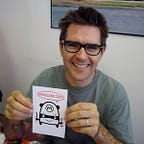

The folks at Dremel have been featuring different makers as part of their “Meet the Maker” program, and last month they commissioned me to make something for them. I decided to make a simple ukulele. I was happy to do it because I’ve been using a Dremel Moto-Tool since I was 12.

I participated in a Facebook Q&A, offered some tips on Twitter, and made a ukulele from scratch. To make it, I referred to the free plans for the acoustic travel uke, available from Circuits and Strings. Here are my build notes. This could be a fun family project.

As much as possible, I like to use materials I already have at home. For the neck, I used a piece of wood that was destined for the recycling bin. I’m glad I didn’t toss it out. I think it is pine, but I’m not sure. It’s 1.5 inches wide, .075 inches high, and two feet long. I cut the end as shown, and glued another cut piece to same end, using wood glue. I clamped it and let it set while I went to work on the rest of the uke. I

I bought a 6-pack of 6 x 12 x 0.125 inch plywood on Amazon for $11. I used it for the body of the guitar and the fretboard. How did I know how to space the frets? I just held another uke against the new fretboard and marked the spacing with a pencil. If you don’t have a uke on hand, here’s a fret spacing calculator. Using a square — like the one shown — against a piece of wood’s factory edge is a good way to ensure parallel and perpendicular lines.

You can see that I used square toothpicks for frets. They work great, and are easier than fret wire. I removed the protruding ends with nail clippers and rounded them with my Moto-Tool.

Here’s a photo of the freshly glued frets and how I clamped them for drying.

The body is made from the same craft plywood. At first I tried to make a square body but then I realized it would be too short for the bridge. This was one of many mistakes I made along the way. I ended up making a rectangular body. The cut-out on the left is for the neck.

When gluing the body together, I used a bunch of scrap pieces of wood with right angles for bracing.

Instead of regular tuners, I used zither tuning pegs. C.B Gitty sells a 4-pack for $4.19. (Don’t forget to buy a tuning key!)

Here’s a block of wood glued to the inside of the body for the zither pegs to fit into.

Back to the neck: I used a rasp to quickly round the edges of the neck, followed by sandpaper. I made a bridge with a few scrap pieces of plywood glued together and shaped it with Dremel 8220 variable-speed cordless rotary tool.

After gluing the neck and body together, I painted a geometric fireball on the front. I then sprayed many coats of acrylic sealer on the uke, then strung it. Here’s the finished instrument (see if you can spot the glaring mistake):

If I make another one like this. I’m going to use regular tuning pegs. It’s a bit of a hassle using the zither key to tune the ukuele.

Here’s a sample of the sound. (The uke sounds better than I can play it):

Many thanks to Dremel for supporting me with this build!