ever wonder why youve veritably never seen (nor will ever see?) a tesla with any sort of (harvey) dent or (christopher) bump on it (especially if it’s a newer make)?

I mean hell if i got rear-ended or bumped up on a corner through no fault of my own (even if it were my fault), yes id look to…

repair it ASAP. Especially if it were a newer make. but something tells me these tesla guys manage not to get rear-ended to begin with by essentially slaving themselves out and therefore doing everything in their physical power to drive as if they’re pulling oxen (a very sad image indeed).

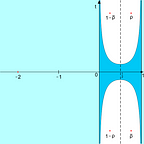

In the event, b/c of this giga-casting move, as a tesla guy, turns out you’re as fragile as a piece of blown glass† at the front and rear end of the car (even if its safety standards aren’t at stake). Perhaps you can say something like the glass can withstand heat like a Pyrex for it (see benefits disclaimer below), but where does that get you on the road where over half the time collisions are in no way you’re fault?

so hallelujah the aluminum involved in the process is highly recyclable†† for otherwise one bump and an entire chunk of metal would be wasted. You’d still be out some 1/3rd the price of the car (?), but at least there’d be some certainty another sucker would line up for the same…shortcut.

Aye, we’re in the land of shortcuts. What is it about certain people and their need for shortcuts?? Sure in this case apart from the significant cost reduction* and efficiency gains, the shortcut maybe even confers some bona fide end user benefits, but at the end of the day, what does it tell you when one of the poster boys for the industrial revolution, the capitalist bourgeois pulse, the single best example of using capital-intensive outlays as the starting point for ever more extensive capital outlays (fossil industry) in a bid to seize wealth that otherwise could be used toward (much) greener substitutes, aka, the car industry en masse, concludes it too wants to adopt the same shortcut? (*which in theory can get passed on to the consumer, much like what’s happened with so much of what’s imported from China.)

I don’t mean to sound too opinionated without the requisite knowledge/expertise, this last consideration therefore implies (to me anyway) that whatever “innovation” to be lauded here sounds about as consumer friendly (or as inspired per se), as any one of the myriad ways our friendly capitalist overlords (aka the CEOs) have taken to make consumer goods (as a category) of cheaper quality and certainly less durable each and every year of my adult life running. Then, only to be logged as productivity gains in the econ books, it serves as the gnarly basis with which these last give themselves pay raises year after year in total disproportion to the boots on the ground not just making the machinery which makes things so, but paying for and consuming such lesser products to boot.

Alas, this giga-molding move sounds fine for the end product characteristics of the battery tray and that’s about it. Bumps on the road, the basic reality of interfacing in such dense grids as Manhattan for example, simply can’t be made so prohibitively costly. Unless the motive for the switch also targets some haphazard* metric for road safety, in which case the industrialist-formerly-known-as-E should be in line for some sort of Nobel prize, as a car manufacturer how can you possibly justify such a brazen redefinition of the equilibrium between cost, and for lack of a better term, fragility? (*But again recall because of rogues on the road who’ll be around for at least another few decades until every car on the planet implements this shortcut such speculation fails to convince.)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Footnotes:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

†:

Yet the article above clearly implies you would get as great or better safety in a tesla with thinner metal finishes, which the giga-casting process doesnt support (yet).

The process of blowing glass involves heating glass until it is molten and then shaping it by blowing air into it through a tube. This traditional craft has been used for centuries to create a wide range of glass products, from decorative items to scientific apparatus. When considering the structural and end quality of blown glass, several factors come into play:

### Structural Considerations:

1. **Annealing:**

— Glass needs to be annealed properly to relieve internal stresses. This involves slowly cooling the glass to room temperature in a controlled environment. Improper annealing can lead to internal fractures and reduced structural integrity.2. **Uniform Thickness:**

— Ensuring uniform thickness is crucial for the structural integrity of blown glass. Variations in thickness can lead to uneven stress distribution, making the glass more prone to breakage.3. **Blow Patterns:**

— The pattern and direction of blowing play a role in the final structure. Skilled glassblowers carefully control the amount and direction of air blown into the molten glass to achieve the desired shape without compromising its strength.4. **Compatibility of Glass Types:**

— Different types of glass have varying coefficients of expansion. When combining different glasses, compatibility must be considered to prevent cracking due to thermal stress.### End Quality Considerations:

1. **Clarity and Transparency:**

— For many applications, especially in decorative pieces and glassware, clarity and transparency are crucial. The glass must be free of imperfections, bubbles, and other visual defects.2. **Surface Finish:**

— The surface finish should meet the desired specifications. It can range from a smooth, polished surface to a textured or frosted finish, depending on the intended use of the glass.3. **Color Consistency:**

— If colored glass is used, ensuring color consistency is essential. Variations in color can affect the aesthetic appeal of the final product.4. **Dimensional Accuracy:**

— The finished glass product must meet the specified dimensions. Precision is especially critical for glass components that will be part of larger assemblies.5. **Chemical Stability:**

— Some applications require glass to be chemically stable, resisting reactions with substances it may come into contact with. This is crucial for scientific and laboratory glassware.6. **Thermal Resistance:**

— Depending on the application, the glass may need to withstand high temperatures without warping or breaking. Thermal resistance is particularly important in industrial and scientific contexts.### Suitability for Specific Applications:

Not all glass products are interchangeable, and the suitability of the finished glass for a particular application depends on factors like:

- **Intended Use:**

— Glasses used in art and decoration may have different requirements compared to those used in laboratory equipment or architectural features.- **Environmental Conditions:**

— The glass must be suitable for the environmental conditions it will be exposed to, whether it’s extreme temperatures, humidity, or other factors.In conclusion, while blown glass can result in beautiful and versatile products, achieving the desired structural and end quality requires a combination of craftsmanship, careful control of the blowing process, and consideration of the specific application for which the glass will be used. Attention to details such as annealing, thickness, clarity, and dimensional accuracy is essential to ensure the glass meets its intended purpose and remains durable over time.

Default (GPT-3.5)

††: In the future, because as of now there seems to be the implication that giga-casting requires non-recycled, pure AL alloy.