The Art and Science of Plant Location Strategy

Data Mastery Series — Episode 19: Strategic Site Selection for Logistic Efficiency

In today’s fast-paced global economy, the efficiency of logistics plays a pivotal role in defining the success of businesses. As companies strive to meet the ever-evolving demands of customers and maintain a competitive edge, the strategic selection of plant locations emerges as a crucial element. This decision not only impacts operational costs but also influences the agility and responsiveness of the supply chain. In this episode, we delve into the art and science of selecting optimal sites for new plants, a key strategy for minimizing logistic distribution costs and maximizing overall business efficiency.

Recap of Our Journey:

In our ongoing exploration of supply chain insights, we have covered:

- Time Series Forecasting (EP1, EP2, EP3, EP4, and EP5)

- Economic Order Quantity (EOQ) (EP1 and EP2)

- Pricing Strategies (EP1)

- Distribution Network Optimization (EP1)

As we continue from EP-1 of Distribution Network Optimization, we invite readers who haven’t yet explored this topic to start there for a foundational understanding. Here, our focus is on optimizing the selection of new plant locations to further enhance logistic efficiencies.

Continuing Our Tale:

After Zara’s initial success with basic Distribution Network Optimization, resulting in significant cost savings in logistics, she realized further reductions could be achieved by establishing a new coffee roasting plant. To explore this, she scheduled a meeting to discuss the best strategies for plant location selection.

In this episode, we use a case study approach without delving into specific data and coding. Our analysis follows the CRISP-DM framework (Learn more about CRISP-DM, click here.)

Business Understanding:

Our goal is to minimize distribution chain costs by establishing a new coffee roasting plant without adding new machinery.

Data Understanding and Data Preparation:

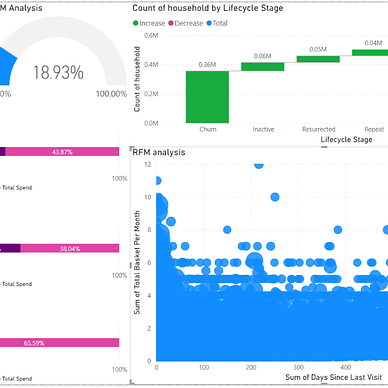

Currently, we have two coffee roasting plants in central and northern Thailand that supply numerous coffee shops across the country, as shown in the figure below.

Modeling (for New Plant Phase 1):

This phase involves installing a new plant without adding new coffee-roasting machines. We will reallocate machines from existing plants to the new site. The optimization process will consider various factors such as distance, capacity constraints, capacity allocation, business strategy, etc. The resulting layout is shown below.

The figure above demonstrates significant improvements in distance and logistics efficiency achieved by adding the new plant without investing in new machinery. This case study illustrates how data analytics can enhance business competitiveness.

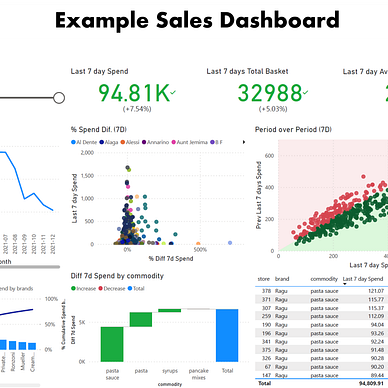

Modeling (for New Plant Phase 2):

Following the establishment of the new southern plant, the business is considering adding another plant in the northeastern region, a large area without existing facilities. The below graphic shows how adding the new plant without having to buy new machinery significantly increased distance and logistics efficiency.

Visualization Insights and Implications:

The visualization results from the comparison across three scenarios — with two plants, two plus one new plant, and three plus one new plant — reveal a significant reduction in the coverage area of each coffee-roasting plant. This strategic expansion and reallocation lead to several key benefits:

- Cost Reduction: The area reduction directly correlates to shorter distribution distances. This efficiency not only lowers transportation costs but also reduces the overall operational expenses associated with logistics.

- Improved Service Levels: By strategically locating plants closer to consumer hubs, we ensure faster delivery times, contributing to higher customer satisfaction. This proximity allows for more agile responses to market demands and enhances the reliability of the supply chain.

- Enhanced Sustainability: The reduced travel distances for distribution not only cut costs but also lower the environmental impact. Shorter routes mean decreased fuel consumption and reduced carbon emissions, aligning with the growing need for sustainable business practices.

These improvements underscore the importance of strategic site selection in logistic optimization. By leveraging data analytics, businesses can make informed decisions that yield economic benefits while also contributing to sustainability goals.

Concluding Notes

In closing, this episode on Strategic Plant Location Strategy demonstrates the critical role of data analytics in enhancing logistic efficiency, reducing costs, and promoting sustainability in supply chain management. We hope these insights inspire and guide businesses to make informed, strategic decisions in an increasingly competitive market. Your thoughts and experiences are invaluable to this discussion, so please feel free to share them. Join us in our next episode for more in-depth exploration of supply chain analytics and strategies.

Thank you for joining me in this exploration. Your engagement and experiences enrich our journey. Please feel free to share your thoughts, questions, or insights below, or connect with me on

Medium: medium.com/donato-story

Facebook: web.facebook.com/DonatoStory

Linkedin: linkedin.com/in/nattapong-thanngam