EOQ Essentials: EOQ, Safety Stock, Reorder Points, and More.

Data Mastery Series — Episode 16: The Art of EOQ (Part 2)

Connect with me and follow our journey: linkedin.com/in/nattapong-thanngam

As we delve deeper into supply chain insights, here’s a quick review of our series so far:

- EP1 Time Series Basics: Explored main forecasting methods and evaluated key metrics.

- EP2 Descriptive Analytics I: Discussed the importance of past data and how to visualize it.

- EP3 Descriptive Analytics II: Covered centrality, variability, and localization metrics and introduced handy Python tools for data work.

- EP4 Forecasting Visuals: Showcased line charts and other visuals for time series data.

- EP5 Sales Predictions: Summarized top methods for forecasting sales.

- EP6 EOQ Fundamentals: Introduced the foundations of Economic Order Quantity, focusing on optimizing inventory and reducing costs.

Continuing our Tale

After implementing basic EOQ in her coffee shop business, Zara quickly recognized its limitations, particularly assumptions like constant demand and instantaneous receipt of materials. Seeking more advanced insights, she consulted Donato to explore the nuances of EOQ further.

Put yourself in Zara’s position. What more would you need to know? How can you realistically apply EOQ in a business where demand and lead times are unpredictable? In this episode, we’ll delve into EOQ adaptations for varying demand, dynamic lead times, safety stock (SS), and reorder points (ROP).

In episodes EP1 through EP5 of “Time Series Forecasting,” we centered on the customer-facing side of the “Coffee Cafe.” Now, just like in EP6, we shift our focus to the supply side, exploring the journey from the “Roasting Facility” to the “Coffee Cafe.”

Understanding EOQ and Its Assumptions

The Economic Order Quantity (EOQ) is calculated using the formula: EOQ = √(2 * D * S / H). Key assumptions here are that the demand is steady and known, and that materials are instantly replenished, indicating a zero lead time.

Diving Deeper: Reorder Points, Safety Stock, and Lead Time:

- Reorder Point (ROP): It signifies the level at which new inventory should be ordered to avoid stockouts. The formula is:

ROP = (Average Daily Demand × Lead Time) + Safety Stock - Safety Stock (SS): A protective buffer against unforeseen demand spikes or supply disruptions. Its calculation often accounts for both lead time and demand variability:

SS=Z×√{(Standard Deviation of Demand² ×Average Lead Time) +(Average Demand² × Standard Deviation of Lead Time²)} - Lead Time: The duration between placing an order and receiving it. Illustrated below is a graph depicting a variable lead time, typically ranging from 2–3 days.

Step 1: Using the Same Dataset from EP6

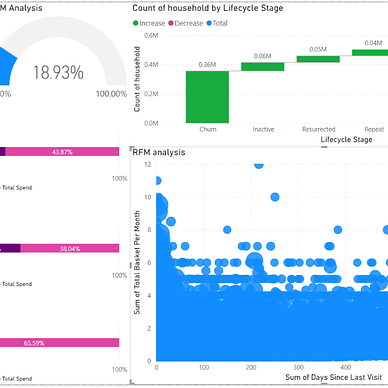

The dataset simulates 4 SKUs (A-D), each demonstrating distinct demand patterns:

- SKU-A has an increasing trend with seasonality.

- SKU-B shows a decline trend with seasonality.

- SKU-C moves sideways with seasonality.

- SKU-D exhibits random, abrupt spikes in demand.

Step 2: Parameter Calculation

While EP5 covered parameters from index 0–9, to determine ROP and SS, we need to delve deeper. This involves computations for average demand, standard deviation of demand, average lead time (rounded up for simplicity), lead time’s standard deviation, and an assumed customer service level (95%). The below table presents these results.

Step 3: Tracking Inventory Movements

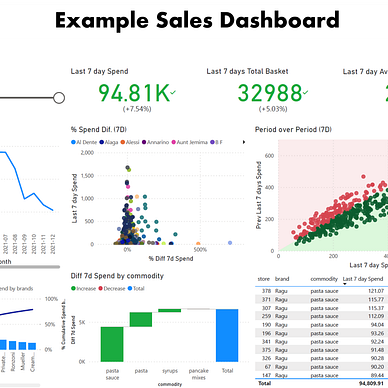

Using a similar table layout as in EP5, The inventory pattern for SKUs A, B, C, and D has been shown.

Though these charts exhibit the baseline EOQ approach, real-world applications of EOQ offer more sophisticated techniques to further optimize costs. Some of these include:

- Periodic EOQ Ordering: A method where reorders occur at fixed intervals. Here’s a sample of its impact:

- Silver Meal Technique: An approach designed for cost minimization over periods. Sample output follows:

Additionally, there are other EOQ variants suited for different scenarios, such as multi-product EOQ, unit discount EOQ, step discount EOQ, and one-time discount EOQ, each of which finds its application in various business setups.

Concluding Notes

Navigating the complexities of inventory management requires not just theoretical knowledge but also a hands-on understanding of various tools and techniques. This exploration into EOQ and its many facets is a testament to the importance of melding theory with practice. As with all business strategies, adaptability and continual learning are key. I invite you to remain curious, challenge assumptions, and always strive for optimization. Let this series be a starting point, not an end, in your supply chain mastery journey.

Thank you for your engagement and trust throughout this exploration. I look forward to sharing more insights and learnings with you in the future. Until next time, happy optimizing!

Please feel free to contact me. I am willing to share and exchange ideas on topics related to data science and supply chains.

Medium: medium.com/donato-story

Facebook: web.facebook.com/DonatoStory

Linkedin: linkedin.com/in/nattapong-thanngam