The Art and Science of Logistic Distribution Optimization

Data Mastery Series — Episode 18: The Concept of Clustering in Logistic Distribution

Connect with me and follow our journey: linkedin.com/in/nattapong-thanngam

Recap of Our Journey:

In our ongoing exploration of supply chain insights, we have delved into:

- Time Series Forecasting (EP1, EP2, EP3, EP4, and EP5)

- Economic Order Quantity (EOQ) (EP1 and EP2).

- Pricing Strategies (EP1).

This episode explores the complexities of managing distribution networks as businesses scale up. We’ll discuss how to optimize logistic distribution for multiple outlets, using the case of our protagonist, Zara.

Continuing our Tale

Zara’s enterprise, now thriving with robust data analytics in sales forecasting, EOQ, and pricing strategies, has entered a phase of expansion. The inauguration of a new coffee roasting plant has ushered in a fresh set of challenges, the most pressing being the optimization of her logistic supply chain distribution to enhance efficiency and reduce costs. Joining hands with Donato, a veteran in logistics, they embark on this crucial mission.

Understanding Distribution Network Optimization:

Distribution Network Optimization is an essential aspect of logistics management, aimed at enhancing the efficiency and effectiveness of how goods move from points of origin to destinations. The goal is to configure the distribution network in such a way that it ensures timely and cost-effective delivery while maintaining high service quality.

In this context, we focus on a specific optimization technique: creating clusters for both roasting plants. This approach involves grouping coffee shops based on their geographic proximity to each roasting plant, thereby streamlining the distribution process. By forming these clusters, we can significantly reduce transportation distances and times, leading to lower costs and improved service levels.

Benefits of distribution network optimization

- Cost Reduction: By finding the most efficient routes and distribution methods, businesses can significantly lower transportation and warehousing costs.

- Improved Service Levels: Optimized networks ensure timely deliveries, enhancing customer satisfaction and loyalty.

- Increased Flexibility: With a well-structured distribution network, businesses can quickly adapt to market changes, demand fluctuations, or supply chain disruptions.

- Enhanced Sustainability: Efficient distribution networks contribute to reduced carbon footprints by minimizing unnecessary travel and optimizing resource usage.

In this exploration, we will apply the CRISP-DM framework to guide our analysis. (To learn more about CRISP-DM, click here.)

Business Understanding:

Our objective is to minimize the costs in the distribution chain.

Data Understanding and Data Preparation:

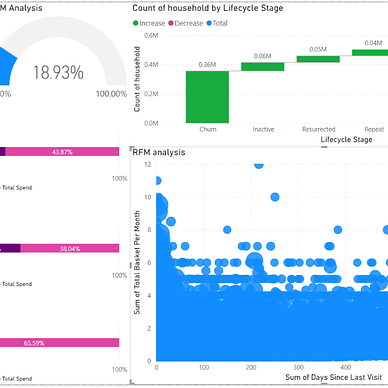

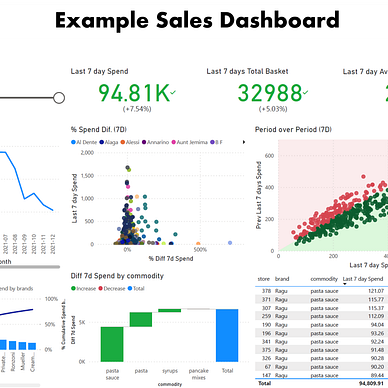

For a realistic simulation, we’ve chosen a popular coffee brand in Thailand as our model. The project’s data is split into two distinct periods:

- First Period: This phase documents approximately 509 coffee shops serviced by a single coffee roasting plant located in the Bangkok area.

- Second Period: Marking significant business growth, the number of coffee shops has expanded to 999. Additionally, a new roasting plant has started operations in the North, necessitating an overhaul of the distribution network for optimization.

The following figures provide a visual representation of this data

(Phase 1: blue markers, Phase 2: green markers).

Modeling Phase 1:

- In the first phase, a single coffee roasting plant with a capacity of 4,500 units addresses the needs of all the coffee shops, which collectively demand 3,520 units. Due to having only one roasting plant in this phase, we do not implement clustering at this step.

Modeling Phase 2:

- With the expansion in Phase 2, we employ linear programming techniques to optimize the distribution network. The objective function is set to minimize the distance between plants and shops, while ensuring demand does not exceed supply.

The simulation results reveal interesting dynamics in the distribution network due to capacity constraints and geographical considerations:

- Bangkok Plant at Full Capacity: Despite an overall supply exceeding the plant’s capacity, the Bangkok plant operates at its maximum due to its strategic location near a large number of coffee shops. This results in some remaining capacity at the North plant.

- Distribution Strategy Adjustment: To efficiently utilize the Bangkok plant’s capacity and cover the southern region, some coffee shops near Bangkok are actually supplied by the North plant. This strategic decision ensures a balanced distribution network, catering effectively to all areas.

In my professional experience, implementing clustering in Distribution Network Optimization yields significant benefits. It effectively reduces costs by streamlining delivery routes. Additionally, service levels are enhanced due to quicker and more reliable deliveries. Sustainability is another key advantage, as optimized routes lead to reduced carbon emissions. This approach not only boosts competitiveness but also paves the way for a business’s success by enhancing efficiency and customer satisfaction.

Concluding Notes

As we wrap up this episode on logistic distribution optimization, we’ve seen the power of data and analytics in transforming supply chain management. I hope this has inspired you to leverage data science for your business’s growth. In our next episode, we’ll focus on selecting optimal locations for new plants, further exploring data-driven strategies.

Thank you for joining me in this deep dive into the world of logistic distribution optimization. I look forward to sharing more insights and experiences. As we gear up for our next episode, keep challenging the norms and optimizing your strategies. Your engagement and experiences enrich our collective journey. Feel free to share your thoughts or questions below, or connect with me on LinkedIn or Facebook.

Please feel free to contact me. I am willing to share and exchange ideas on topics related to data science and supply chains.

Medium: medium.com/donato-story

Facebook: web.facebook.com/DonatoStory

Linkedin: linkedin.com/in/nattapong-thanngam